- 1490 NE Pine Island Rd, Unit 3C, Cape Coral, Florida 33909, US

- usmarket@cytec.de

- +1 (833) 298-3287

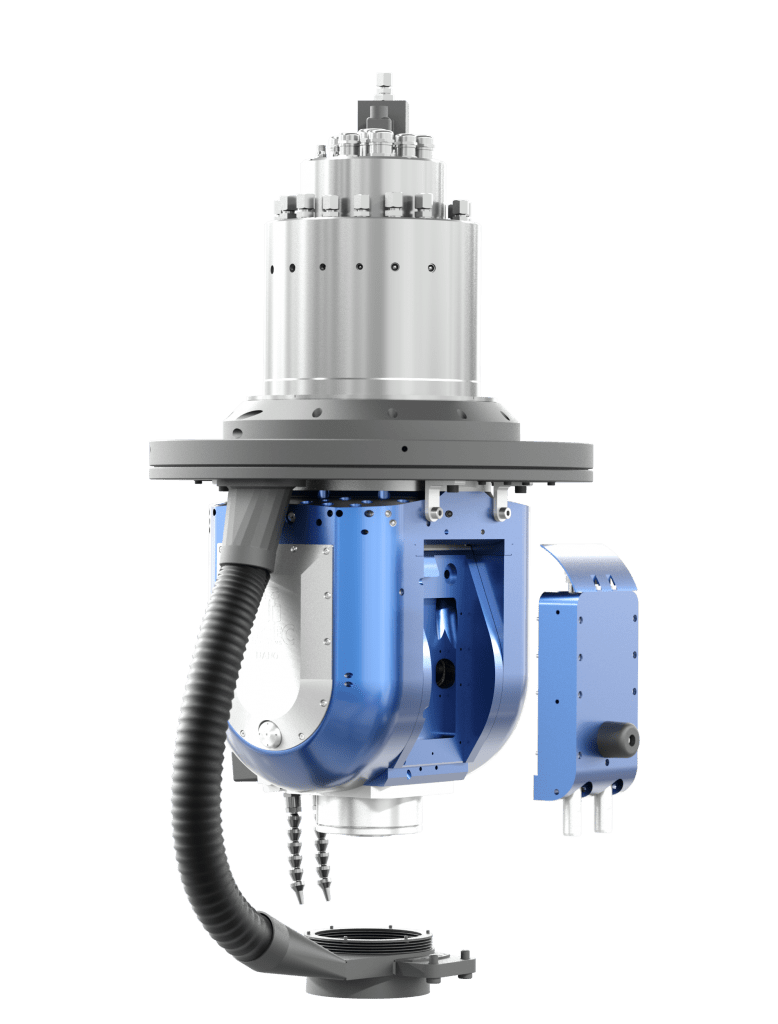

The CYTEC Nano Series milling heads represent the most compact solution within the CYMILL product line. Specifically engineered for high-precision machining of lightweight materials such as carbon fiber composites, plastics, and aluminum, the Nano Series combines minimal installation space with exceptional dynamic performance.

| Power (S1/S6): | 13 / 18 kW |

| Torque (S1/S6): | 20 / 28 Nm |

| Max. Speed: | 24,000 rpm |

| Tool Interface: | HSK-A63 |

| Length: | 347 mm |

| Power (S1/S6): | 26 / 34 kW |

| Torque (S1/S6): | 33 / 42 Nm |

| Max. Speed: | 15,000 rpm |

| Tool Interface: | HSK-A63 |

| Length: | 347 mm |

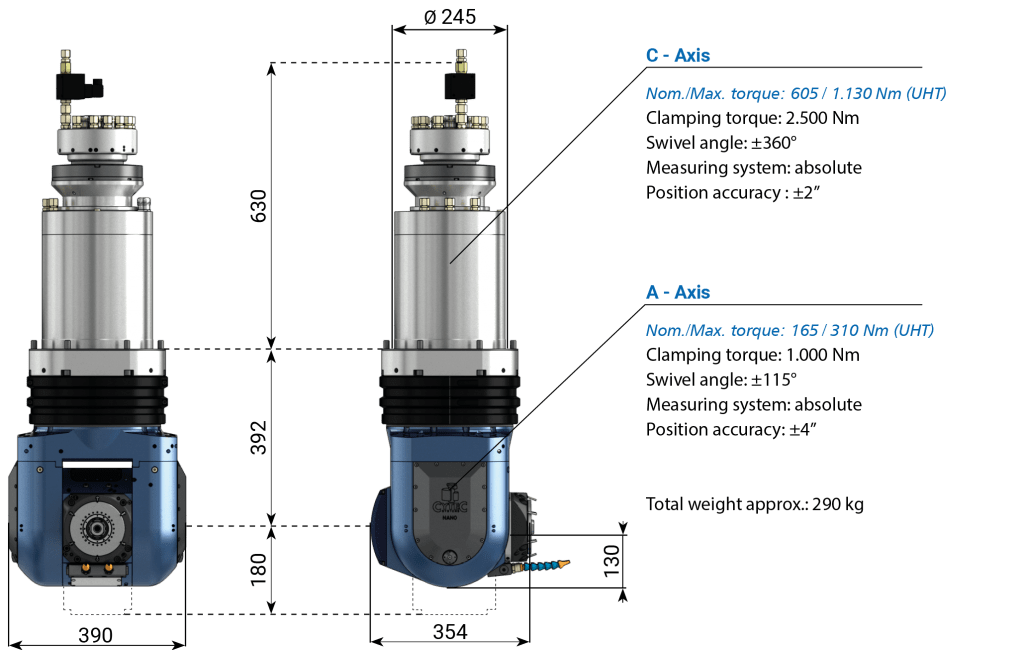

has the ability to simultaneously position the cutter in space. This is achieved by controlling the A-axis and the C-axis simultaneously. By combining the movements of the two axes, the Fork Milling head can position the cutter in any desired position in space, allowing for complex and precise cuts to be made on the workpiece.

This type of cutter is particularly suitable for the production of complex tools and shapes where high precision and flexibility is required.

CYTEC NANO-Series Milling Heads

Ultra-compact head with 115°/360° motion, ±5″/±2″ accuracy, 700/2500 Nm clamping torque – perfect for precise micromachining and tight spaces.

CYTEC S -Series HD Milling Heads

Slim Heavy-duty head with ±110°/360° motion, 2,400 Nm clamping torque, ±2″ precision – built for structural part machining with maximum rigidity.

CYTEC M-Series HD Milling Heads

Compact milling head with high torque, hydraulic clamping, ±120°/±360° rotation, 2″ accuracy, for dynamic 5-axis machining in tight spaces.

CYTEC G-Series HD Milling Heads

Compact milling head with high torque, hydraulic clamping, ±120°/±360° rotation, 2″ accuracy, for dynamic 5-axis machining in tight spaces.

IMPRINT

PRIVACY