- 1490 NE Pine Island Rd, Unit 3C, Cape Coral, Florida 33909, US

- usmarket@cytec.de

- +1 (833) 298-3287

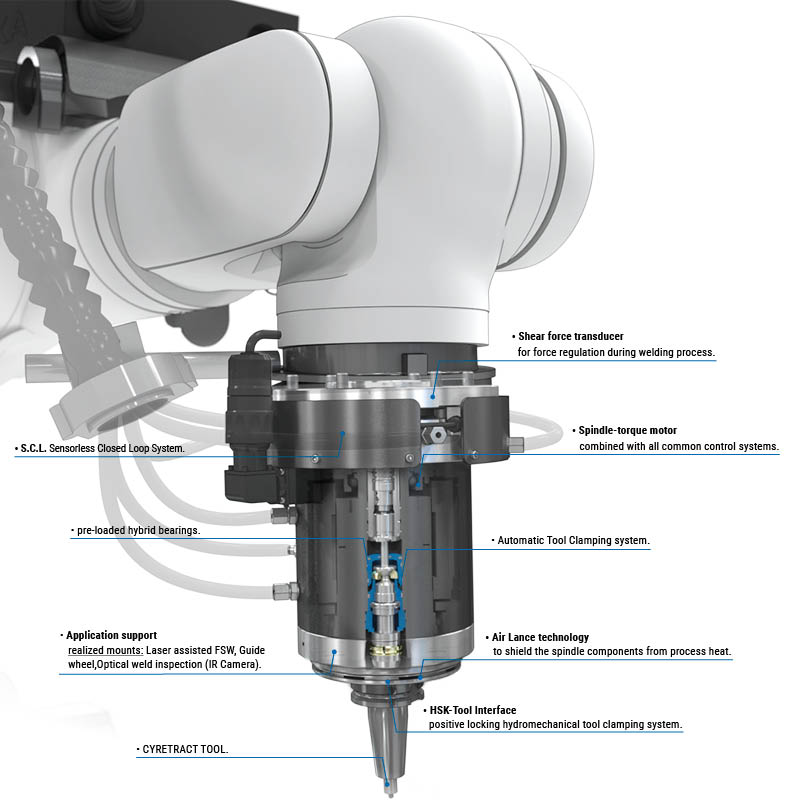

Characteristics :

• HSK tool interface with hydromechanical Cytwist tool clamping system

• CyTorque motor (combinable with all common control systems)

• Pre-loaded CyRt hybrid bearing

• Shear force transducers to regulate forces during the welding process

• Rotary union for clamping and release hydraulics

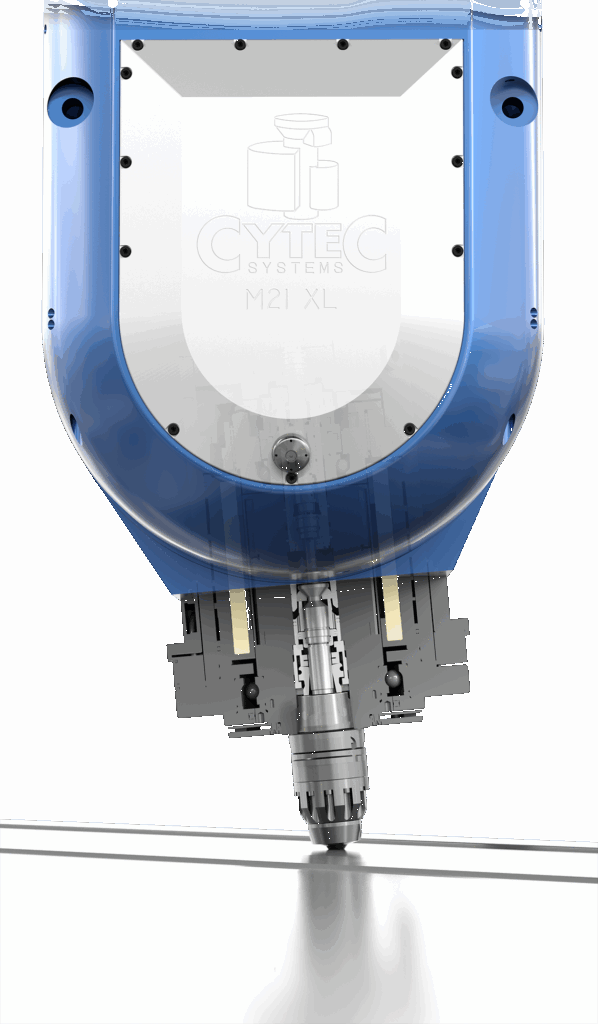

Characteristics :

• HSK tool interface with hydromechanical Cytwist tool clamping system

• CyTorque motor (combinable with all common control systems)

• Pre-loaded hybrid bearing

• Shear force transducers to regulated forces during the welding process

• Rotary feedthrough for clamping and release hydraulics

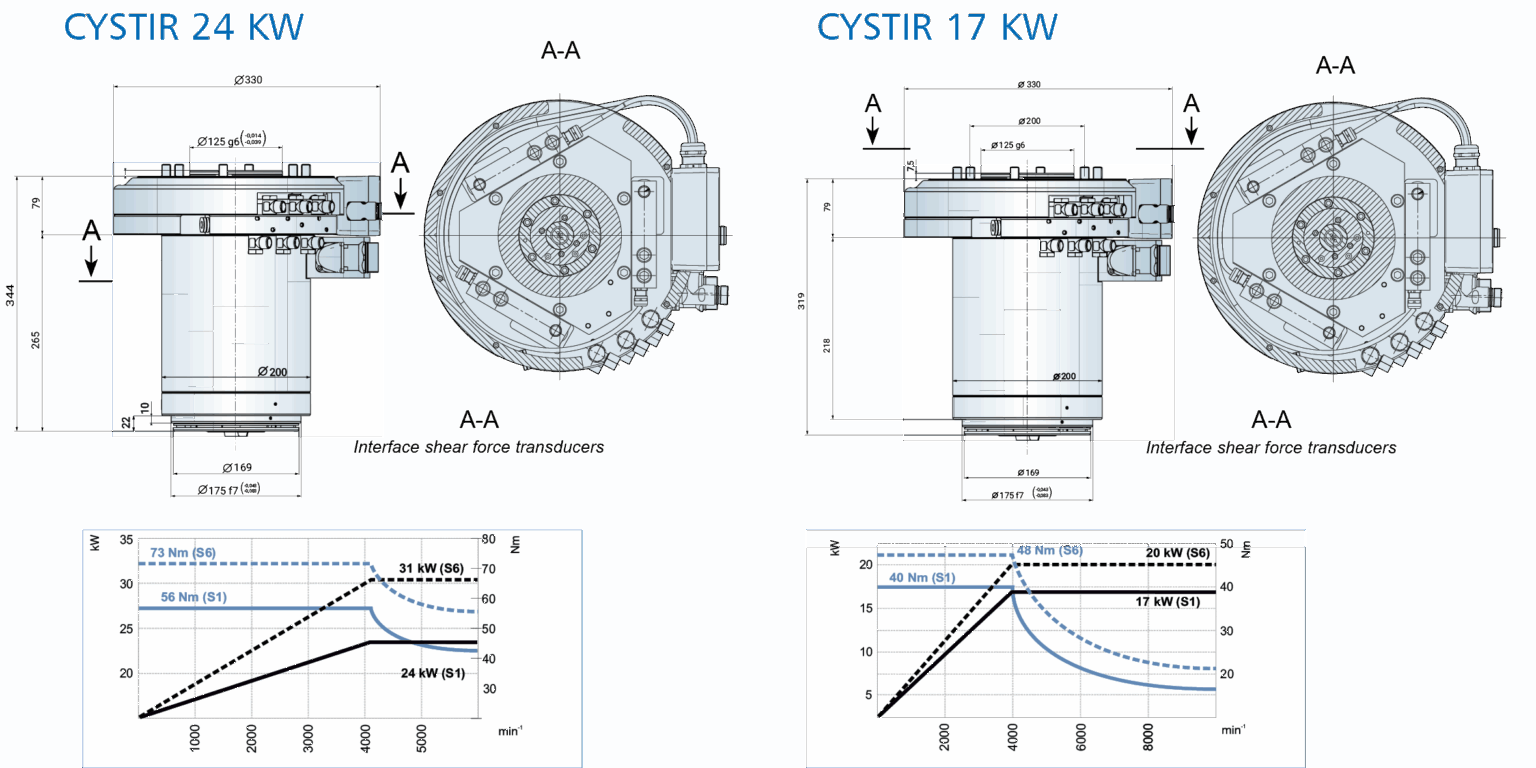

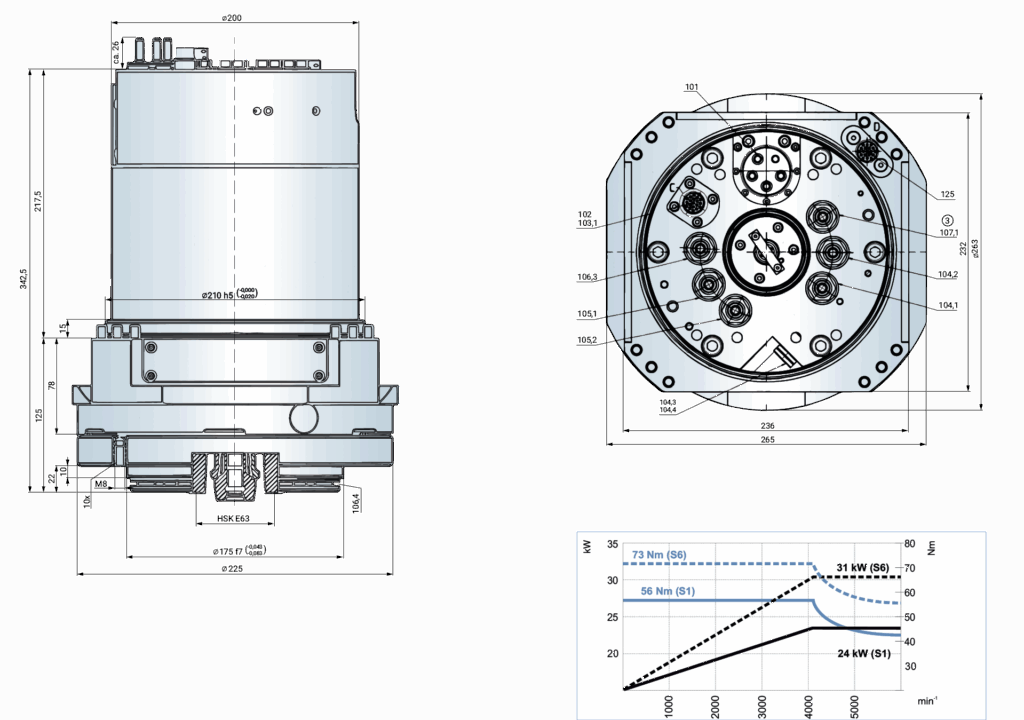

| Specification |

CYSTIR 17 kW Robotic Head |

CYSTIR 24 kW Robotic Head / Forkhead |

CYSTIR 42 kW Forkhead G30 |

|---|---|---|---|

| Power (S1/S6) | 17 / 20 kW | 24 / 31 kW | 42 / 53 kW |

| Torque (S1/S6) | 40 / 48 Nm | 56 / 73 Nm | 400 Nm |

| Rated Speed | 4,000 rpm | 4,050 rpm | 1,000 rpm |

| Max Speed | 9,000 rpm | 5,000 rpm | 7,000 rpm |

| Current (S1/S6) | 48 / 57 A | 42 / 54 A | 200 A |

| Specification | CYSTIR 17 kW | CYSTIR 24 kW | CYSTIR 42 kW |

|---|---|---|---|

| Max. Axial Load | 15 kN | 15 kN | 40 kN |

| Max. Radial Load | 5 kN | 5 kN | 20 kN |

| Weight | 88 kg | 95 kg | 350 kg |

| Specification | CYSTIR 17 kW | CYSTIR 24 kW | CYSTIR 42 kW |

|---|---|---|---|

| Tool Interface | E63 / A63 | HSK | HSK-A100 (Ø125) |

| Clamping Force | 22 kN | 22 kN | 40 kN |

| Clamping Pressure | 55 bar | 55 bar | 75 bar |

| Clamping Monitoring | CyCon K11 | CyCon K11 | – |

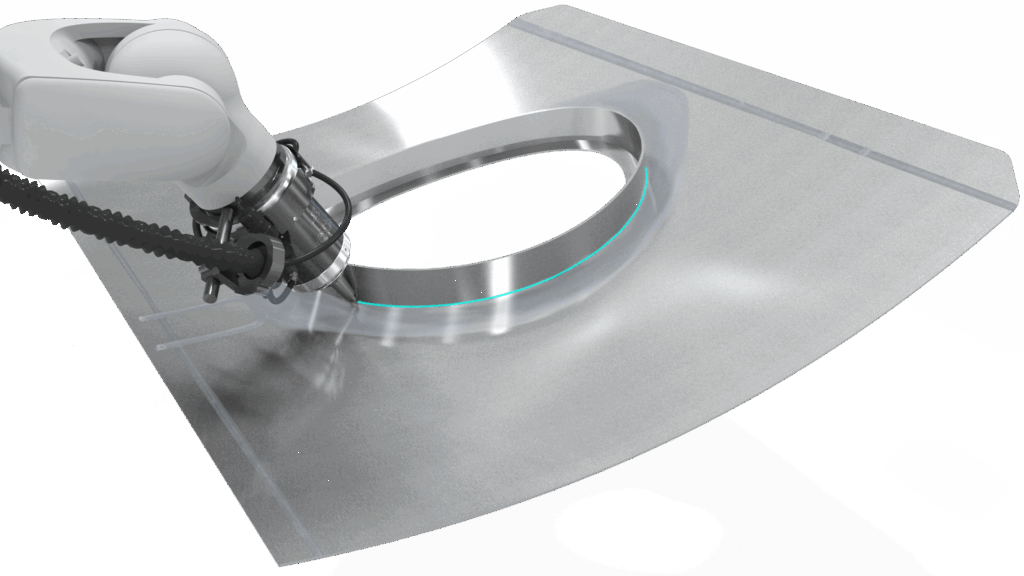

Aircraft Engineering

Space travel

Defense

Aircraft industry

Automotive industry

Fuel tanks

Aggregate

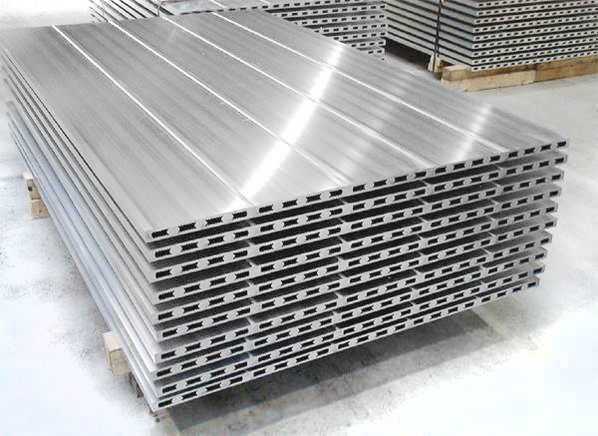

Coil joining

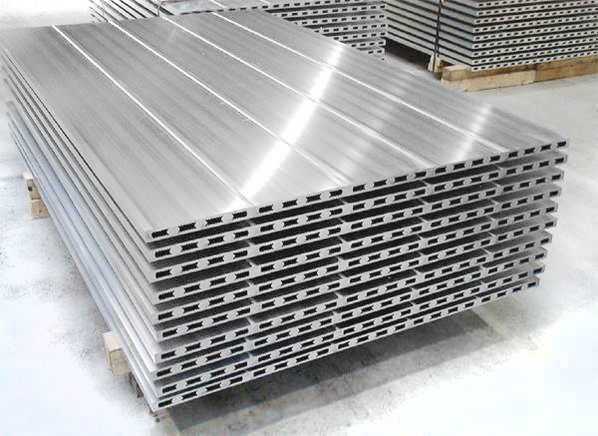

Connection of deck plates

…and many other production parts in different markets

IMPRINT

PRIVACY