- 1490 NE Pine Island Rd, Unit 3C, Cape Coral, Florida 33909, US

- usmarket@cytec.de

- +1 (833) 298-3287

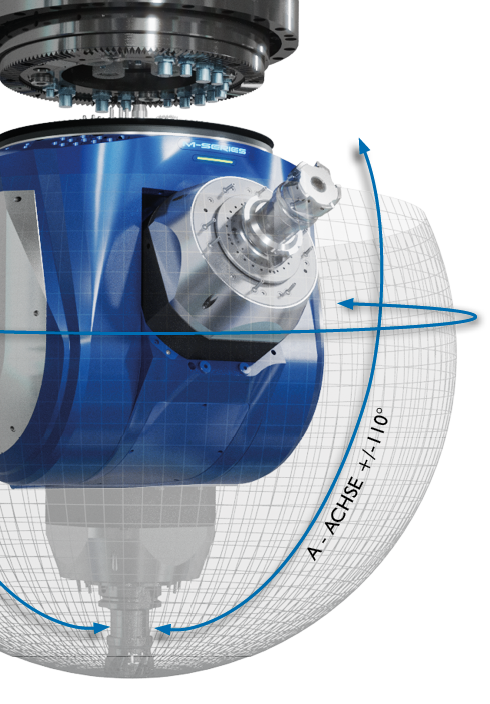

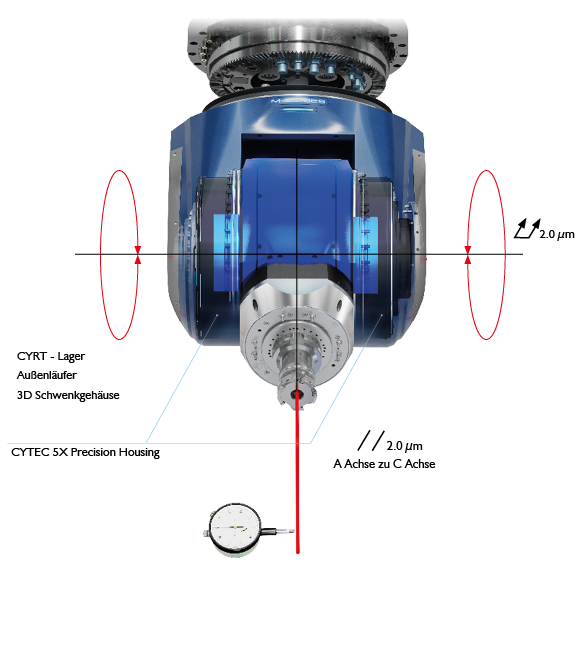

has the ability to simultaneously position the cutter in space. This is achieved by controlling the A-axis and the C-axis simultaneously. By combining the movements of the two axes, the Fork Milling head can position the cutter in any desired position in space, allowing for complex and precise cuts to be made on the workpiece.

This type of cutter is particularly suitable for the production of complex tools and shapes where high precision and flexibility is required.

The optional Infinite Turning C-Axis for the milling head enables uninterrupted simultaneous machining for unparalleled accuracy and productivity.

Engineered for the highest demands, the Infinite C-Axisensures superior results on the most challenging parts.

CYTEC’s universal milling head is the ideal solution for horizontal machining centers – especially in combination with rotary table systems. Its slim design and wide selection of spindle options make it perfectly adaptable to a variety of applications.

Offering the best power density on the market, it sets new standards in efficiency and compactness. Whether in high-precision positioning mode with 0.0005° accuracy or in full 5-axis simultaneous machining, it delivers outstanding performance.

Also suitable for vertical machines, this milling head is the perfect choice for tool centers, providing maximum flexibility, precision, and dynamics for the most demanding machining tasks.

IMPRINT

PRIVACY