- 1490 NE Pine Island Rd, Unit 3C, Cape Coral, Florida 33909, US

- usmarket@cytec.de

- +1 (833) 298-3287

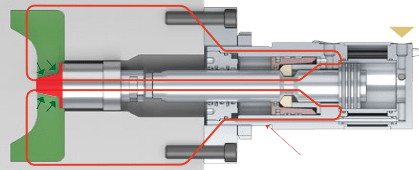

The mode of operation is similar to series CP-H…-L, but here the segments create an additional preload to provide that the core touches the mould surface reliably. The locking slide and segments have a characteristic cone shaped contour which enables the piston rod to lock within a defined tolerance range. Elasticities which can occur commonly in the mould construction are compensated. This tolerance range in the final position can reach up to 1 mm stroke. The self-inhibiting locking is maintained permanently and as a result the pressure supply is not necessary.

In this range a preload is generated that guarantees reliable operational process and high workpiece quality.

The red curve displays the force distribution as it is achieved in the locked position with positive lock.

Core and piston rod withstand the high counter pressure during the following injection cycle definitely. The core does not recede!

Core pull interlocking cylinders

Application:

Mould attachment injection molding tools – die casting

Two standardised installation lengths. Strokes from 10 up to 100 mm.

Option: customer specific modifications and dimensions always possible. 100% more holding forces in the locked position by means of enlarged piston diameter.

IMPRINT

PRIVACY