- 1490 NE Pine Island Rd, Unit 3C, Cape Coral, Florida 33909, US

- usmarket@cytec.de

- +1 (833) 298-3287

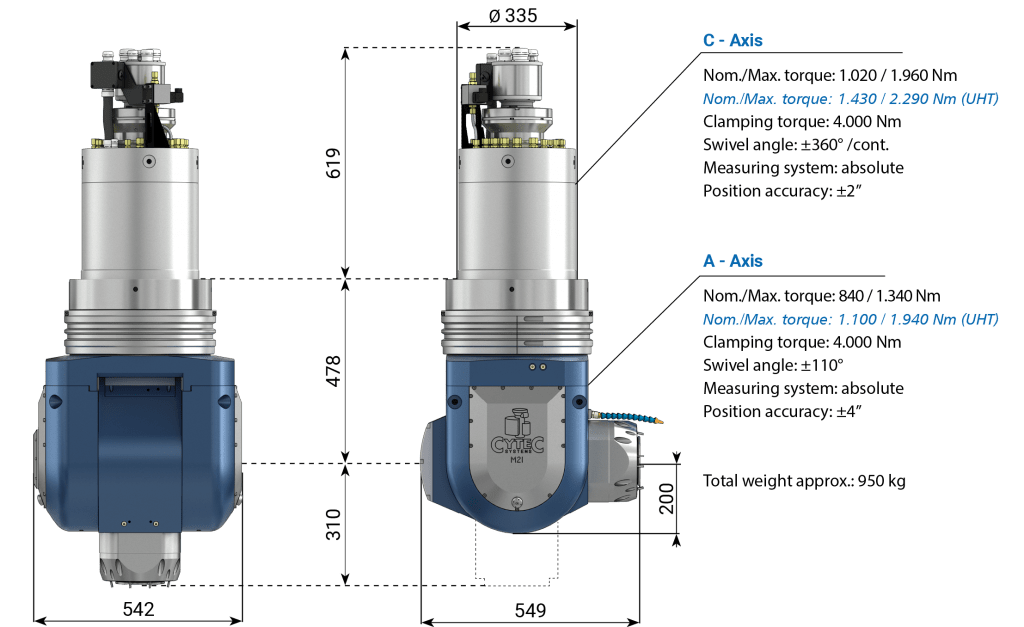

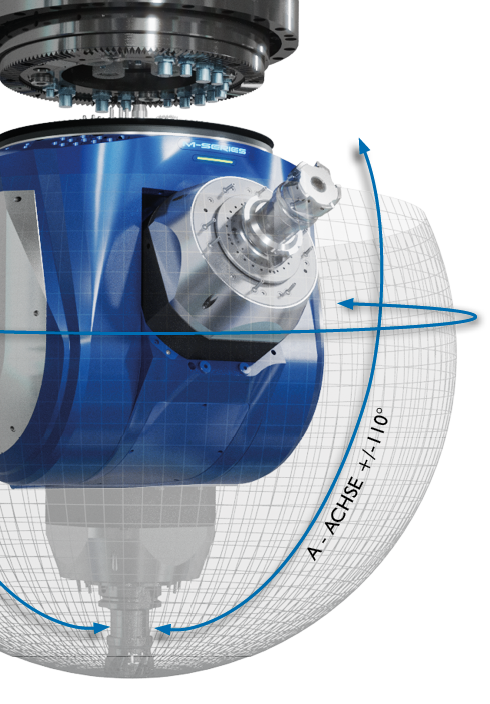

has the ability to simultaneously position the cutter in space. This is achieved by controlling the A-axis and the C-axis simultaneously. By combining the movements of the two axes, the Fork Milling head can position the cutter in any desired position in space, allowing for complex and precise cuts to be made on the workpiece.

This type of cutter is particularly suitable for the production of complex tools and shapes where high precision and flexibility is required.

IMPRINT

PRIVACY